Mobile Drum Lifting Equipment

Mobile Drum Lifting Equipment

Mobile drum lifting solutions built specifically for your work process. Engineered Ergonomics designs and develops drum lifting equipment that can be adapted to lift and manipulate steel, fiber and plastic drums in a variety of sizes, diameters and weights.

Customized Drum Lifting Solutions

All of our mobile drum lifters are designed with the end user in mind. We design solutions that are easy-to-use and promote workplace safety and efficiency. We start by gathering information specific to your operational process, including

- Area of work space

- Work environment – requirements and regulations

- Drum size, diameter, weight and material

- Functional needs including weight, rotating, pouring, dispensing, emptying and releasing payloads

After our team has studied your process and requirements, we will develop a solution tailored to your specific needs.

Extensive Industry Experience

Extensive Industry Experience

Over the years, Engineered Ergonomics has designed and developed a wide range of drum lifting equipment for a wide variety of needs. We have worked closely with clients in the pharmaceutical and chemical industries to provide solutions that meet or exceed their strict requirements.

Built to Integrate with Your Process

Your work flow is unique, and our goal is to develop a solution that complements your existing process. We achieve this by designing a solution based on your facility, operational requirements, manpower and industry standards. Our goal is to increase operational efficiency, employee safety and overall productivity.

We offer customized lifters, accessories and end effectors to design the perfect solution for your facility, including:

OD Grippers – Designed for applications where the core of the roll needs to remain open. OD grippers use a gentle, controlled force to pick up large rolls, without damaging the product.

Wash Down Enclosures – Stainless steel frames and enclosures that are IP 66 compliant and can be cleaned with a hose or power washed with various cleaning solutions.

Wash Down Enclosures – Stainless steel frames and enclosures that are IP 66 compliant and can be cleaned with a hose or power washed with various cleaning solutions.

Explosion Proof – This option provides for Explosion Proof enclosures for the control panel, Power Pack (batteries) w/ Charger along with motor(s) for ATEX Compliance in European Zone 1 and US NEC 505 Zone 1 Hazardous Locations. For other certifications please contact us.

Explosion Proof – This option provides for Explosion Proof enclosures for the control panel, Power Pack (batteries) w/ Charger along with motor(s) for ATEX Compliance in European Zone 1 and US NEC 505 Zone 1 Hazardous Locations. For other certifications please contact us.

Low-Built Legs – Allow mobile lifters to access rolls from machines with under a 4” clearance height.

Low-Built Legs – Allow mobile lifters to access rolls from machines with under a 4” clearance height.

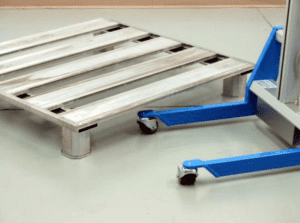

Spacer Pallet – Spacer pallets are used to provide clearance for lifter legs. Place shipper pallets on the aluminum spacer pallet. These are also available with rotator rings allowing operators to position loads in specific locations.

Spacer Pallet – Spacer pallets are used to provide clearance for lifter legs. Place shipper pallets on the aluminum spacer pallet. These are also available with rotator rings allowing operators to position loads in specific locations.

While these are some of our more popular accessories, this is in no way an exhaustive list of our options. Engineered Ergonomics specializes in the design and development of customized drum lifting equipment that will resolve safety and inefficiency issues. Please contact Engineered Ergonomics today to discuss your needs.